Since everyone is so about their “family business”, I decided to release my laboratory notebook, from 2012, of how I discovered electrical paper (semiconducting paper). I am a disabled student, and sometimes I get inspiration.

I am trying to make a nanofiber conductive textile, here is a quick lab-writup-

I am attempting a 4 method experiment on creating a conductive textile using silver nanowires from blue-nano; One of my 4 methods is conjectured that I may be able to make a conductive polymeric textile matrix using the sonicator/vortex mixer, and the flacktech speed mixer, which then can be then hypothetically (pending conversation with flacktech) chopped up and put into the filter fabrication in an equalized matrix.

the other 3 methods are

pancake method

melting method (theoretically with a very sensitive oven using possible pressurized chamber)

topical spray method with adheasive.

(this is a semi-pre-lab-writup) pending convo with flacktech:

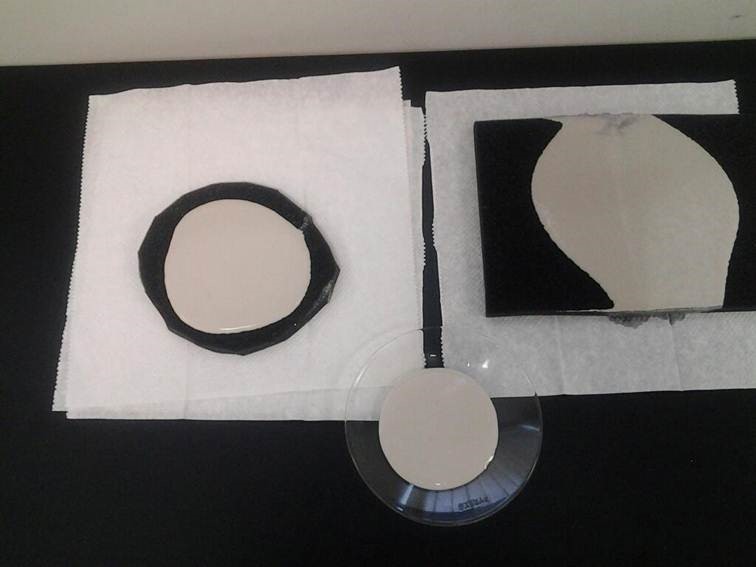

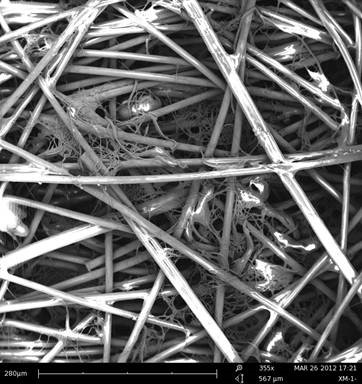

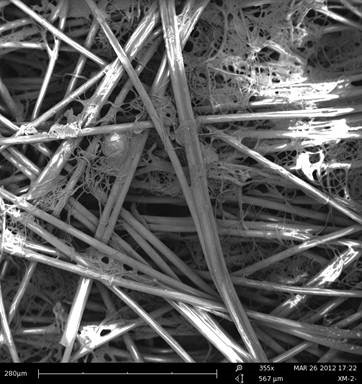

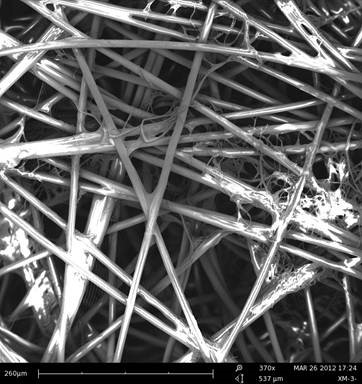

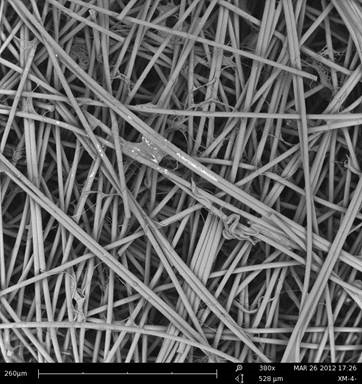

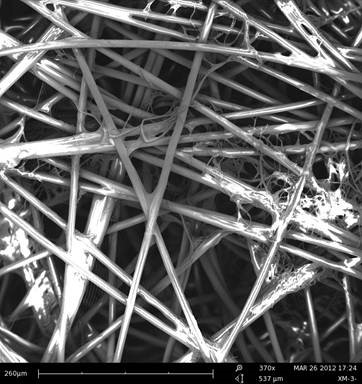

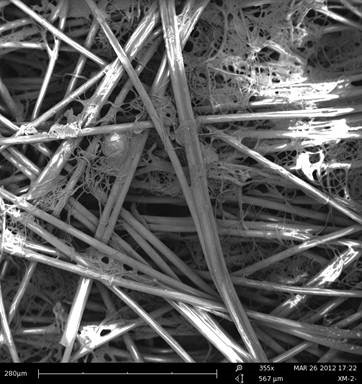

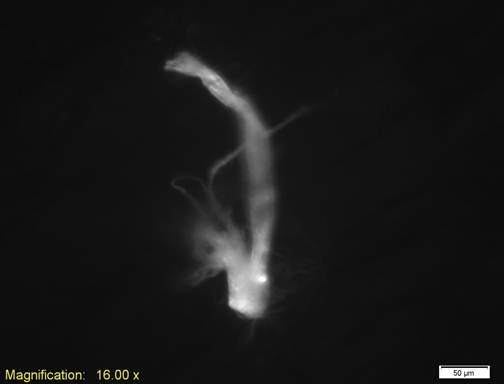

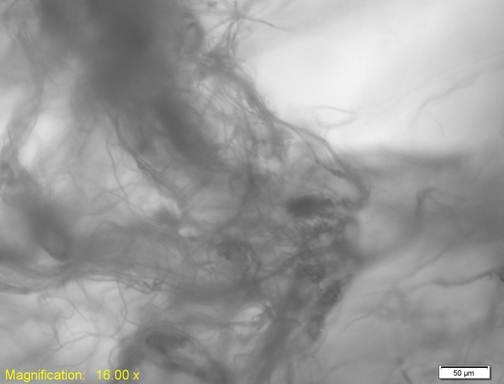

This is what nanofibers look like: Sample textiles:

These fibers are cellulose acetate

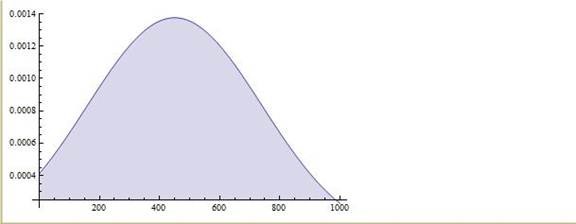

These are 400-500nm Low range=200; SD=280-300 High range=micrometer scewed towards 300-500 diameter and 2-10mm in length

Blue nano silver molarity:

Hey Aaron –

It appears that modern telephony still has a ways to go, as I could only make out every second or third word. I’d love to give you more info on how to utilize our products. Please feel free to give me a call or email. In the meantime, here’s a quick answer to your question below: we ship with concentrations at 10mg/ml, or 1.25wt% for small quantities. Does Xanofi have a large jug of nanowires, or a small vial/syringe? The jugs are shipped at 20mg/ml, or 2.5wt%.

Sincerely,

David Schroder

Vice President, Business Development

Pasted from <http://email09.secureserver.net/webmail.php?login=1>

LOGS:

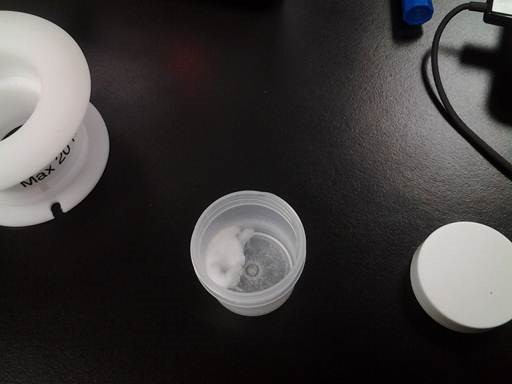

Weight of vessel 7.242

Weight of small fibers and cap 20.7 (dry)

mix1- trying sample mix @5 minutes @1000 RPM for testing

tempurature (hand temp)

mix2-

2.403g fibers cellulose acetate

mixing @2000 RPM@5min

bottle is 13.1g

13.1g−2.4g→ 10.7g→bottleweight of the 20gmaxload cup

mix3 4.189g @3000RPM @5min

mix4 1.726g fiber cellulose acetate

add 25 ml water test tube (di)

vortex @3000rpm for 1:30

take photo

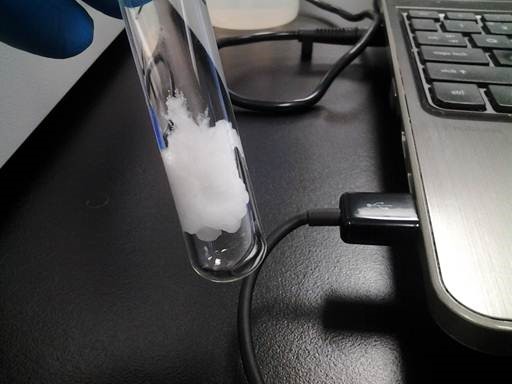

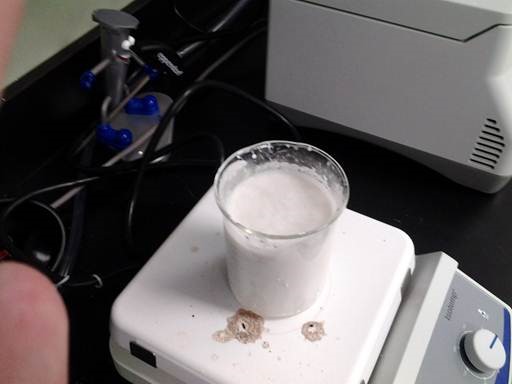

I seem to have made a vortex swirl in the fibers

mix5

2.44g fiber

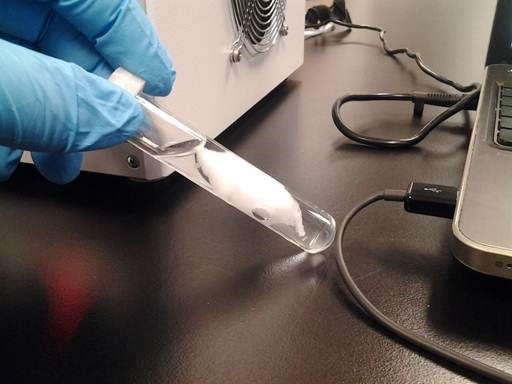

stuffed into test tube with dowel and added DI water

the fibers are so tight that water cannot pass through

Sonicating 5 minutes-sonication has no effect macroscopically

mix6

3.17g nanofiber using 2mm glass beads spin mix at 2000 rpm for 5 minutes approximately 30 beads (mistake, mixed at 3000 rpm)

the 2mm beads did not mix with the substance at all, just beat the surface of the mix

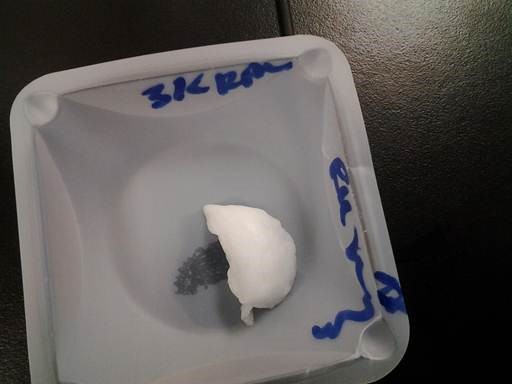

mix7

using 6mm beads at 3000 rpm

4,48 grams added 15 beads and 20 ml of water 2500 rpm @5 min total weight unknown

tempurature-not warm to the touch

cutting appears successful will photograph

putting into 100 mL beaker for observational analysis

beads separated

photograph taken in beaker and emailed

this may be an acceptable cutting method

mix 8

28.4g fiber

mix bottle 22.44g

added 30 ml of di water

bottle of random CNT shacking bottle for 3 min +100microliter of cnt+100microliter of cnt+200microliter of cnt+300microliter of CNT

mixing at 3500 at 5 min

this is just a random test to see if I can get the carbon to mix through the material uncut

in the photograph it appears the carbon nanotubes cannot get into the material uncut and are just forming at the surface. Let me try a cut the sample.

using 6mm beads about 20

it wouldn’t cut 19.2 grans ubstead

another 30 ml of water

regrinding at 3500 rpm

at 5 minutes

material would not cut…

let me attempt hand cutting it and then mixing it

took a photograph

ok I hand cut it with the same amount of reagents and put it back inside the mixer at 3500 rpm at 5:00 minutes

lets see if it will cut.

the fiber is very strong, it gave more resistance to being separated than I thought-

I tried grinding it with no effect. Maybe on large quantities I cannot grind it

I put less in and got it to grind

now I added some water in and started grinding the rest of it.

It seems to be the amount of fiber vs. water to make it grind.

I am grinding it in three different batches

final sample had to grind again

I have it all grinded now the entire sample

now I am putting into a seive-funnel strainer

mix9- 1.4g into test tube

added 20 ml of water

I got kicked out of the lab today at 3:00 I need to go back and finish what I started possibly on Monday.

Day 2

Ok I came back to work, and I saw that mix 7 was dried into a nice layer.

Conversation with pete shows that I use 50g/meter of solution of slv-nw-90 so I fibers unknown.

I am going to try to mix up a larger batch at 3500 RPM

The nanofibers in mix 7 hardened into a nice matte just in airdry

Mix10

22 g nanofiber being mixed

I have to have much more water than fiber and it will mix correctly. Added 6mm balls also

I began using tap-water I am going to make a high volume mix.

Shacking top strain

it is still rather chunky

Checking bottom strain

Top strain has more of a gelatonous quality

Straining more

The reason why the there must be a much higher amount of water for grinding is because the balls need room to move…if there is not enough water then the balls cannot build up any kinetic energy

Switching to the largest cup size for faster mixing (this is taking forever)

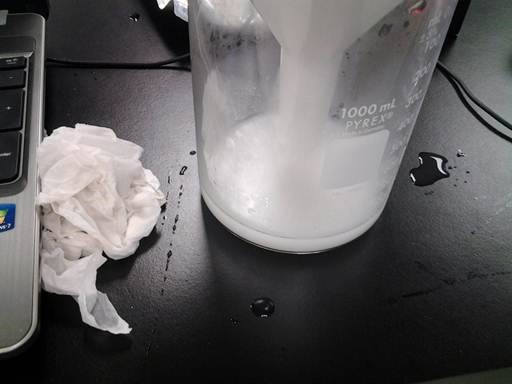

Heating up strained material to 135F to let water boil off’

Change tempurature on the pad to 155C

Mixing entire batch up and straining @3500 RPM 5 minute batches then straining

Change temp on pad to 225

Change temp on pad to 255

Change temp on pad to 285C

Change temp on pad to 320 C

Continue grinding rest of sample

Turn on chunky sample to 300C

Quickly turned off to risk burning

http://ultimatepapermache.com/paper-mache-recipes

This fella uses 3:1 pulp to glue I am not sure what to do exactly.

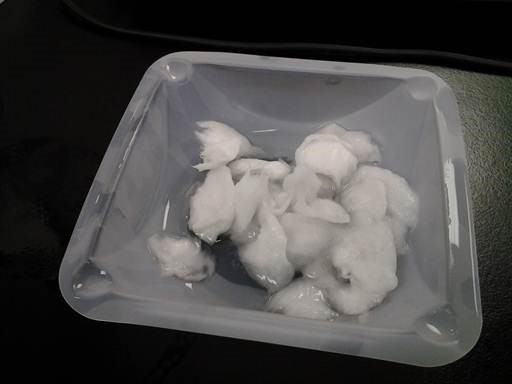

Ok I boiled off the first set of fine particles; photo shown, I will combine with the nanofiber matrix

Boiling off the chunks—hand stir—

WARNING- bad experiment, I ruined a sample. Once you put in small beads they are impossible to get out. I am going to test to see if this can be rolled into a usable material first

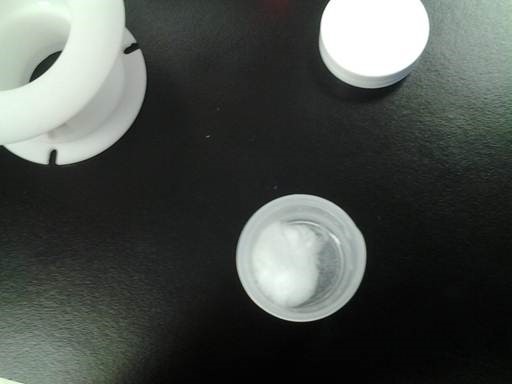

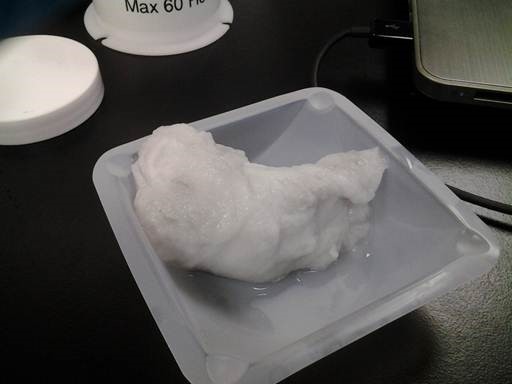

Using the 3:1 ratio of binder to base I found a very nice material for fabrication. Photo included.

As you can see on the left, the 25% glue solution was much easier to pour and lay down without cracking.

However when I attempt to kneed it like dough, the stickyness of the surface tension doesn’t allow for any contact with the material to change its surface or shape once it has been poured, I think it may have been too wet to mess with.

Therefore using only wood glue cellulose and silver nanowires, I think in this method a conductive material can be made, however in a filter application I think just the nanowires with binder may be the best method.

This could be a method to make conductive paper or paper electronics. I am not sure how to get the material to be thin, I think using extrusions, drying and rolling may be able to make this material into sheets.

I will check the laboratory tomarrow and do the spectroscopy, I also need more cellulose fibers to use all of the silver, and wood glue. I will pick this stuff up on Wednesday.

I also noticed that this material is an excellent insulator against heat. Once I had a highly concentrated suspension, I had great difficulty heating it up to boil. I gave up instead of attempting to boil off the water and burning the bottom.

Day 3

The application with the 3:1 cut of glue actually worked well. However I think that 3:1 isn’t needed I am going to attempt fabricating with a 5:1 cut.

After 16 hours settling the remaining sample seems to be only a 2mm water separation on top..(photo included)

Spectroscopy looks really bad. I took the batch of unmixed fibers and looked at them…

Mix 2 (2000 RPM)

Mix3 2000 RPM

There is some fluophores embedded in the material, I am not sure why.

Mix 1

Mix1

Mix1

I think I broke down the fibers too much with heat and the size…at any rate they are invisible to the naked eye or the fluorescence microscopeI cannot see them anymore…I don’t see any fibrous matrixes. It may be possible to see them in an AFM…but I am going to wait until the SEM is repaired.

I am going to try another mixture of 5:1 glue to cellulose mix.

100 mL sample remaining mixed 20 ml glue

Spin 5 min 2760 RPM

80 mL remaining

I am going to attempt a silver solution on a slow mix

Shake silver hand 5 min

25 ml solution into 80 mL glue+cellulose@300RPM

Going to attempt a slow mix, 300 rpm looks good

Its nicely mixed…now I will pour between two pieces of foam.

http://en.wikipedia.org/wiki/Conductive_polymers

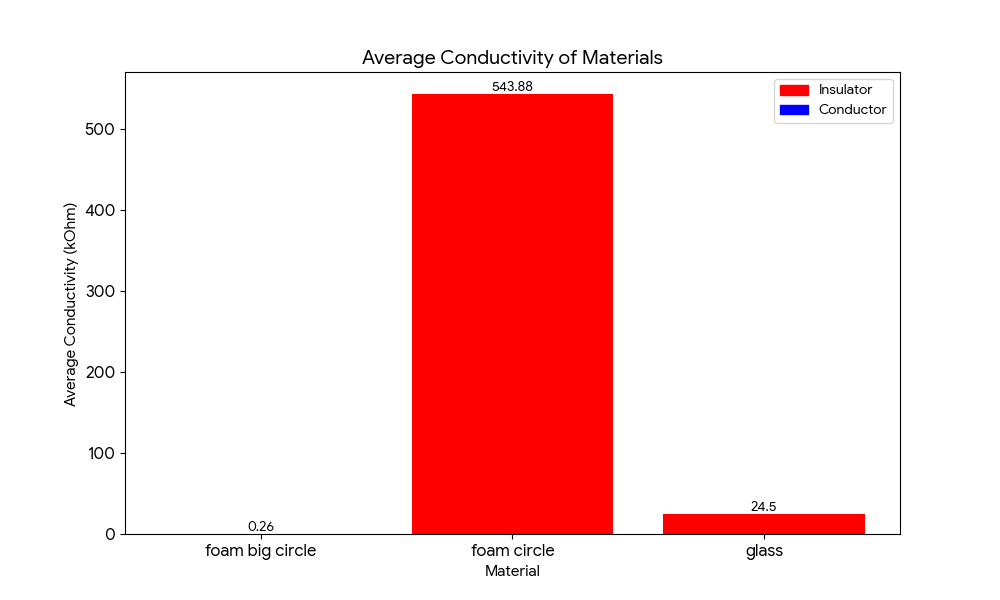

After bringing back to the lab and testing after 5 days of drying. I found that the glass substrate would not get it to work. But It works on the foam somewhere from 10^-3 to 10^-4 scale….which is about silicon…

Look at PLC (programmable logic controlling)

glass

39

22

18

19

foam circle

380

250

525

545

502

565

738

846 kohm

foam big circle

.412

.228

.284

.160

.209

bad side 40 to 60

COMMENT:

If anyone ever wants to do a paper on this subject please let me know. I am tired of secretive businesses who do nothing with my products.